Our related videos

Knowledge

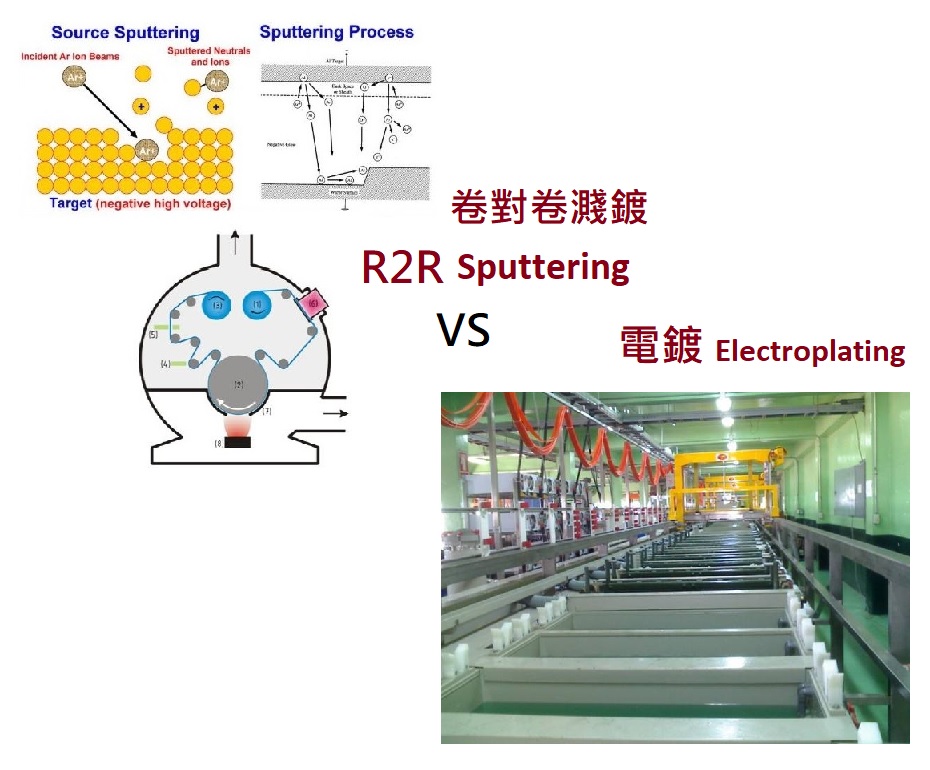

Roll-to-Roll Sputtering vs. Electroplating: Comparing Metal Coating Processes

In modern industry, metal coating technology is widely used in heat sinks, electronic components, functional films and other fields.Among them, Roll-to-Roll Sputtering and traditional Electroplating are the two most common coating methods.

This article will make an in-depth comparison from the perspectives of process principle, environmental protection, cost, coating quality and coating thickness, application scenarios, etc., for reference by R&D personnel and end customers, to help you choose the most suitable coating technology.

TOP Nanometal Corp. is a roll-to-roll sputtering electronic material manufacturer. In addition to its own products, it also provides roll-to-roll sputtering services to assist customers in mass production of flexible electronic thin film products or cooperate with customer RD in early development (MOQ=1 roll). If you have any needs, please contact us.

| Evaluation Dimensions | Roll to Roll Sputtering | Traditional electroplating | Remarks |

| Process principle | Physical vapor deposition (PVD) Ions bombard the target material to deposit thin films in a high vacuum environment |

Chemical electrolytic deposition, which forms a coating by reducing metal ions through electric current | -- |

| Environmental protection | No chemical waste liquid, waste is mainly waste target material (solid), which can be recycled and reprocessed | Contains heavy metal wastewater/waste liquid (such as chromium VI), which requires complex and proper treatment | Sputtering is better |

| Coating thickness | Thinner, usually nanometer to micrometer level (0.1-3um), requires multiple layers of deposition to thicken * Nanoscale is easier, while micron thickness varies depending on substrate and equipment characteristics |

Flexible, usually micron level (1-100um), suitable for thick coating requirements | Electroplating is better |

| Uniformity/precision | High uniformity (vacuum environment control, film thickness deviation <±5%) |

Affected by the electric field distribution, the uniformity of edges/complex structures is low | Sputtering is better |

| Material compatibility | Wide (metals, alloys, support for high melting point materials) | Limited (depends on electrolyte, difficult to plate high melting point metals) | Sputtering is better |

| Production mode | Continuous roll-to-roll production, suitable for large quantities | Batch processing, less efficient | Sputtering is better |

| Equipment cost | High (vacuum system, target material) | Low (tank, power supply) | Electroplating is better |

| Technology maturity | Mature in the field of flexible electronics/solar energy | Mainstream process for traditional heat sink manufacturing | |

| Environmental regulations adaptability | Fully compliant with strict standards such as RoHS and REACH | Facing the risk of environmental regulations being upgraded (such as heavy metal ban) | Sputtering is better |

| Typical application scenarios | Ultra-thin heat sinks, flexible electronic components, high-precision requirements (such as 5G chip cooling) | Thick layer heat sinks, large-size structural parts (such as CPU cooling base) | Scenarios complementarity |

| Core challenges | Thickening technology bottlenecks, high-cost equipment and targets | Environmental compliance pressure, difficulty in improving uniformity | -- |